Product

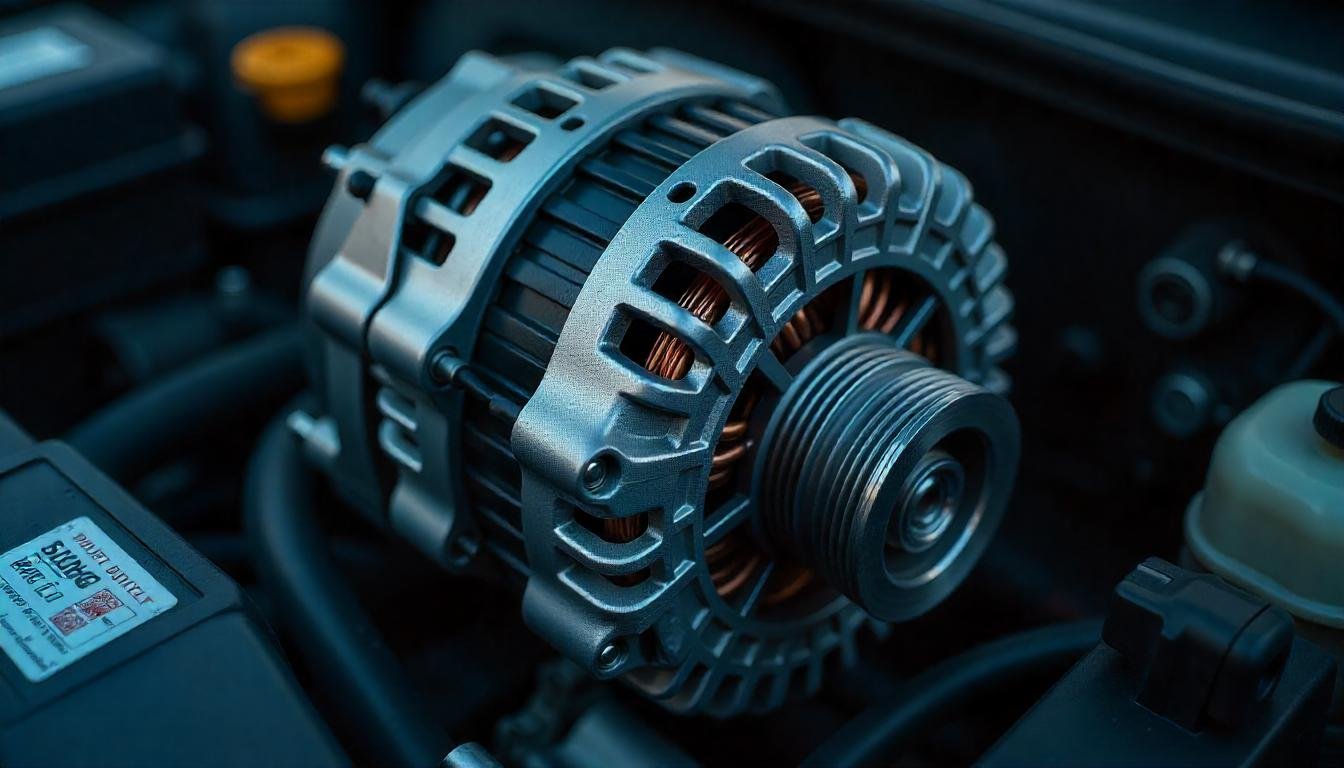

Rotating Electrical Auto Parts of Vehicle’s Electrical System

BLOGS

Blue Agate Properties, Benefits, and Uses Explained

Blue agate, with its enchanting hues and intricate patterns, is more than just a pretty stone. It’s a gemstone revered for its calming energy, emotional healing properties, and spiritual significance. Whether you’re drawn to its visual appeal or its metaphysical attributes, blue agate has something special to offer. Let’s delve deeper into the world of this captivating stone.

What Is Blue Agate?

Blue agate is a variety of chalcedony, a mineral in the quartz family, characterized by its layered bands of soft blue tones. These bands often include white or translucent layers, creating a stunning, ethereal appearance. This gemstone forms naturally over millions of years, making each piece truly unique.

Origins and History of Blue Agate

Blue agate has a rich history that dates back to ancient civilizations. The stone was believed to hold protective and healing properties, often used in amulets and talismans. Early records show its use in Mesopotamian and Egyptian cultures for spiritual ceremonies and as a symbol of divine connection.

Today, blue agate is sourced from various regions, including:

- Brazil: Known for producing high-quality agates.

- Botswana: Famous for its uniquely patterned stones.

- India and Madagascar: Other significant sources of blue agate.

Physical Properties of Blue agate

Blue agate is a unique and captivating gemstone, celebrated for its serene beauty and intricate natural patterns. Its physical properties not only define its visual appeal but also make it a durable and versatile choice for various applications. Here’s a detailed look at the physical characteristics that make blue agate so special:

Color

The defining feature of blue agate is its soft, tranquil shades of blue, often interspersed with:

- White or Translucent Bands: Creating a layered, ethereal appearance.

- Subtle Variations: Ranging from pale sky blue to deeper, almost aqua tones.

This color spectrum gives blue agate its calming and soothing aesthetic, making it a favorite for both decorative and spiritual purposes.

Transparency

Blue agate ranges from semi-translucent to opaque, depending on its formation and mineral content. This variability adds depth and dimension to its appearance, particularly when polished or cut into slices.

Hardness

With a hardness rating of 6.5–7 on the Mohs scale, blue agate is:

- Durable: Resistant to scratches and everyday wear.

- Versatile: Suitable for jewelry, ornamental pieces, and practical tools like coasters or bookends.

Lustre

Blue agate possesses a waxy to vitreous (glassy) lustre when polished. This shiny surface enhances the stone’s natural beauty, emphasizing its bands and intricate details.

Density

The stone has a density of approximately 2.6–2.7 g/cm³, making it relatively lightweight for its size. This characteristic contributes to its practicality in jewelry and other wearable forms.

Structure and Composition

Blue agate belongs to the chalcedony family, a microcrystalline form of quartz. Its structure is composed of fine intergrowths of silica minerals, giving it:

- Toughness: The stone is resistant to breaking or chipping.

- Unique Patterns: Its layered structure creates the characteristic banding seen in blue agate.

Formation

Blue agate forms over millions of years through the slow deposition of silica in volcanic cavities. This process creates its distinct bands and ensures that no two pieces are identical.

Metaphysical Properties of Blue Agate

Blue agate is celebrated for its metaphysical properties, providing both emotional and spiritual benefits:

- Calming Energy: Reduces stress and promotes relaxation.

- Communication Aid: Enhances clarity in self-expression and helps resolve conflicts.

- Emotional Healing: Assists in overcoming past trauma and fostering a sense of inner peace.

This stone is often associated with the throat chakra, which governs communication and self-expression.

Blue Agate in Healing Practices

Blue agate is a cornerstone in crystal healing practices due to its gentle yet effective energy:

- Physical Healing: Believed to alleviate throat-related ailments, regulate hormones, and improve circulation.

- Emotional Healing: Supports overcoming fear, anxiety, and feelings of isolation.

- Spiritual Healing: Strengthens intuition and aids in meditation, enhancing the connection with higher realms.

Uses of Blue Agate

Blue agate is a versatile stone with applications ranging from wellness to aesthetics:

- Jewelry: Worn as necklaces, bracelets, or earrings for personal energy alignment.

- Home Decor: Used in coasters, bookends, and decorative pieces to infuse spaces with calm energy.

- Meditation Tools: Incorporated into meditation practices for focus and spiritual growth.

How to Use Blue Agate in Daily Life

To harness the benefits of blue agate, try these simple practices:

- Wear It: Keep the stone close to your throat chakra by wearing it as a pendant or choker.

- Carry It: Place a small piece in your pocket or bag to carry its calming energy throughout the day.

- Display It: Position the stone in your living or workspace to promote a serene environment.

Blue Agate in Feng Shui

In Feng Shui, blue agate is used to create a harmonious atmosphere by balancing the energy of a space:

- Placement: Ideal for areas where you seek peace, such as bedrooms or meditation rooms.

- Element: Associated with the water element, representing flow, communication, and clarity.

How to Cleanse and Charge Blue Agate

To maintain the energetic properties of blue agate, regular cleansing and recharging are essential:

- Cleansing: Rinse under lukewarm water or smudge with sage.

- Charging: Place in sunlight for a few hours or under the light of the full moon.

This ensures your stone remains vibrant and energetically potent.

Blue Agate vs. Other Agates

Blue agate stands out among other types of agates due to its distinct appearance and specific energy:

| Feature | Blue Agate | Other Agates |

|---|---|---|

| Color | Soft blue with bands | Varied (red, brown, etc.) |

| Energy | Calming and communicative | Grounding or protective |

| Uses | Emotional healing, throat chakra | Root chakra, heart chakra |

How to Identify Genuine Blue Agate

When purchasing blue agate, ensure authenticity by considering the following:

- Visual Inspection: Look for natural banding and a smooth polish.

- Reputable Sellers: Buy from trusted gemstone dealers.

- Price Check: Authentic blue agate is moderately priced; too low may indicate a fake.

FAQs

What are the benefits of blue agate?

Blue agate promotes emotional healing, enhances communication, and brings calming energy to its wearer.

Can blue agate be worn daily?

Yes, its durable nature and soothing energy make it suitable for daily wear.

Is blue agate safe to cleanse with water?

Yes, but avoid prolonged soaking to preserve its natural beauty.

How does blue agate support meditation?

By calming the mind and enhancing intuition, blue agate helps deepen meditative practices.

Can blue agate improve communication skills?

Yes, as it resonates with the throat chakra, it can aid in clear and confident expression.

Where can I buy authentic blue agate?

Reputable online stores, gemstone boutiques, and certified dealers offer authentic blue agate.

Conclusion

Blue agate is a gem of tranquility, offering both aesthetic beauty and profound emotional support. Its calming energy, combined with its rich history and diverse applications, makes it a must-have for gemstone enthusiasts and wellness seekers alike. Whether you wear it, meditate with it, or use it to enhance your living space, blue agate’s soothing presence can bring harmony and balance to your life.

Health & Fitness

Hunter Green Scrubs for Healthcare Professionals

Hunter green scrubs have emerged as a timeless choice in healthcare attire, offering a harmonious blend of professionalism, comfort, and style. With their rich, earthy tone, these scrubs not only provide a calming effect in high-pressure environments but also exude sophistication.

Let’s dive deep into the world of hunter green scrubs, their benefits, styling tips, and how they can enhance your professional wardrobe.

Why Choose Hunter Green Scrubs?

Hunter green is more than just a color—it’s a statement of reliability and calmness. In a field where first impressions matter, these scrubs convey a sense of trustworthiness and competence. Beyond aesthetics, hunter green scrubs are practical for the demands of healthcare environments, offering stain concealment and versatility.

The Psychology Behind Hunter Green

The color green symbolizes balance, harmony, and renewal, which are essential in healthcare settings. Hunter green, being a darker shade, is associated with stability and depth. This color choice helps soothe patients and fosters a sense of well-being, making it a preferred option for professionals working in hospitals, clinics, and other medical facilities.

Material Choices for Comfort and Durability

When selecting hunter green scrubs, material plays a pivotal role. The most common fabric options include:

- Cotton: Breathable and soft, offering all-day comfort.

- Polyester Blends: Wrinkle-resistant and durable, perfect for long shifts.

- Spandex Blends: Provides stretch and flexibility for active professionals.

Choosing the right material ensures that your scrubs remain functional and comfortable throughout your workday.

Styles of Hunter Green Scrubs

Hunter green scrubs are available in a variety of styles designed to cater to the diverse needs of healthcare professionals. Whether you prioritize functionality, comfort, or fashion, there’s a style that will suit your preferences while maintaining a polished and professional appearance. Here’s a closer look at some of the most popular styles of hunter green scrubs:

Classic V-Neck Tops

The V-neck scrub top is a staple in medical attire. Its simple and timeless design makes it a favorite among professionals across various healthcare settings. V-neck tops in hunter green offer:

- Universal Appeal: A flattering cut for all body shapes.

- Functional Pockets: Essential for carrying tools like pens, notepads, or gloves.

- Breathable Fit: Ensures comfort during long shifts.

Mock Wrap Tops

Mock wrap tops add a touch of style while preserving professionalism. These tops mimic the look of a wrap blouse but come without the hassle of tying.

- Elegant Silhouette: Offers a more tailored and feminine look.

- Adjustable Features: Many designs include side-ties or elastic for a customizable fit.

- Practical Design: Often features deep pockets for added utility.

Polo-Style Scrub Tops

For those who prefer a more casual yet polished appearance, polo-style scrub tops are an excellent choice.

- Collared Design: Adds a semi-formal touch to the traditional scrub.

- Button-Up Neckline: Allows for adjustable ventilation.

- Professional Aesthetic: Ideal for roles requiring frequent interaction with patients or visitors.

Sleeve-Length Variations

Scrub tops also come in different sleeve lengths to suit various preferences and workplace climates:

- Short-Sleeve Tops: Ideal for warm environments or high-activity roles.

- Long-Sleeve Tops: Provide extra coverage and warmth in cooler settings.

- 3/4 Sleeve Tops: A versatile option that balances coverage and comfort.

Jogger Pants

Jogger-style scrub pants bring modern athleisure trends into the healthcare world. These pants are both functional and stylish, featuring:

- Tapered Fit: Provides a sleek, contemporary look.

- Elastic Cuffs: Prevent pant legs from dragging on the floor.

- Stretchable Waistbands: Ensures a secure and comfortable fit.

Straight-Leg Pants

A traditional choice, straight-leg scrub pants are a go-to for many professionals.

- Clean Lines: Offer a classic and professional appearance.

- Roomy Design: Provides comfort and ease of movement.

- Adjustable Waistbands: Many include drawstrings or elastic for the perfect fit.

Cargo Pants

For those who require additional storage, cargo scrub pants are a practical option.

- Multiple Pockets: Ideal for carrying small medical tools or personal items.

- Durable Construction: Designed to withstand the demands of busy work environments.

- Versatility: Pairs well with any scrub top style.

Unisex Styles

Unisex scrubs are tailored to suit both men and women, making them a flexible option for teams or individuals:

- Relaxed Fit: Accommodates various body shapes.

- Neutral Design: Appeals to a broad range of style preferences.

- Affordable Options: Commonly available at budget-friendly prices.

Maternity Scrubs

For healthcare professionals who are expecting, maternity scrubs in hunter green provide both comfort and adaptability:

- Stretch Panels: Accommodate growing bellies with ease.

- Soft Fabrics: Prioritize comfort during long shifts.

- Adjustable Features: Include elastic waists or side ties for a perfect fit.

Petite and Tall Fits

Hunter green scrubs are available in petite and tall fits to ensure every professional finds the right length and proportions:

- Petite Options: Shorter inseams and adjusted proportions for smaller frames.

- Tall Options: Longer inseams and adjusted designs for taller individuals.

Best Brands Offering Hunter Green Scrubs

Several brands specialize in creating high-quality hunter green scrubs, including:

- Figs: Known for their luxurious fabric and modern designs.

- Cherokee: Offers affordability without compromising on quality.

- Grey’s Anatomy by Barco: Renowned for their stylish and durable options.

- Dickies: Combines functionality with budget-friendly pricing.

Each brand caters to different needs, ensuring there’s something for every healthcare professional.

How to Accessorize Hunter Green Scrubs

Accessories can elevate the look of your scrubs while ensuring functionality:

- Compression Socks: Choose neutral or complementary shades for added comfort and style.

- Badge Reels: Opt for minimalist designs or fun patterns to express personality.

- Lab Coats: A crisp white lab coat pairs seamlessly with hunter green scrubs.

- Comfortable Footwear: Supportive clogs or sneakers in neutral colors complete the ensemble.

These additions strike a balance between practicality and personal flair.

Caring for Your Hunter Green Scrubs

Maintaining the vibrant hue and durability of your scrubs requires proper care:

- Washing Tips: Use cold water and mild detergent to preserve the color.

- Drying Advice: Air-dry or use low heat settings to prevent fading.

- Stain Removal: Pre-treat stains with gentle cleaners immediately after use.

Following these steps ensures your scrubs remain fresh and professional-looking.

Where to Buy Hunter Green Scrubs

Finding the perfect pair of hunter green scrubs is easier than ever, thanks to a variety of options:

- Online Retailers: Platforms like Amazon, Scrubs & Beyond, and Uniform Advantage offer a wide selection.

- Brick-and-Mortar Stores: Visit local uniform shops for personalized fittings and in-store discounts.

- Brand Websites: Direct purchases often come with exclusive deals and custom sizing options.

Sustainability and Hunter Green Scrubs

Many brands are now incorporating sustainable practices in their production of scrubs. Look for labels that use organic cotton or recycled materials, ensuring your purchase supports eco-friendly initiatives while meeting professional needs.

FAQs

What makes hunter green scrubs a popular choice?

Hunter green scrubs are favored for their professional appearance, ability to conceal stains, and calming psychological impact.

Are hunter green scrubs suitable for all healthcare settings?

Yes, the neutral tone of hunter green makes it appropriate for hospitals, clinics, and private practices.

How do I choose the right size for my hunter green scrub?

Refer to the brand’s sizing chart and consider trying on different fits to find the perfect match for your body type.

What accessories go well with hunter green scrub?

Neutral-toned footwear, white lab coats, and simple badge reels are great accessories for hunter green scrub.

Can I personalize my hunter green scrub?

Yes, many retailers offer embroidery services for adding names, roles, or logos.

How can I ensure my scrubs last longer?

Wash with care, avoid harsh chemicals, and store them properly to maintain their quality.

Product

P87 Stores Brick the Retail Experience

-

Technology2 weeks ago

Technology2 weeks agointernet chicks: A Digital Phenomenon

-

Recipes9 months ago

Recipes9 months agoCrab Brulee Recipe: A Gourmet Delight

-

Recipes9 months ago

Recipes9 months agoSmoothie CCL: A Delicious and Nutritious Trend

-

FOOD2 weeks ago

FOOD2 weeks agoÇeciir: A Journey Through Turkish Cuisine

-

FOOD9 months ago

FOOD9 months agoCornflake Meringue Cookies

-

FOOD9 months ago

FOOD9 months agoNasi Uduk

-

Recipes9 months ago

Recipes9 months agoThe Ultimate Bug Juice Camp Drink Recipe for Fun and Flavor

-

BLOGS9 months ago

BLOGS9 months agoUnveiling the Innovation: BoltBól – Revolutionizing Accessibility and Mobility